Construction details in NL

Construction details characteristic to the times, the climate and choice of materials and their specifications.

Old Gable Image is retained with new insulation to gable

After thorough restoration, the Eiffel building has been transformed into The Student Hotel, lofts and commercial space. For the insulation, an insulation layer of 150 mm on the outer wall was chosen. In order to bring back the old facade image, the profiling of the old facade has been copied exactly. So with all the pilaster strips, floor edges, lintels and water hammer. A hand-worked stucco layer has been applied to it, in which shallow lines have been drawn to imitate the traditional character of the old masonry.

Floor-high glass dishes

By Editors Bouwwereld

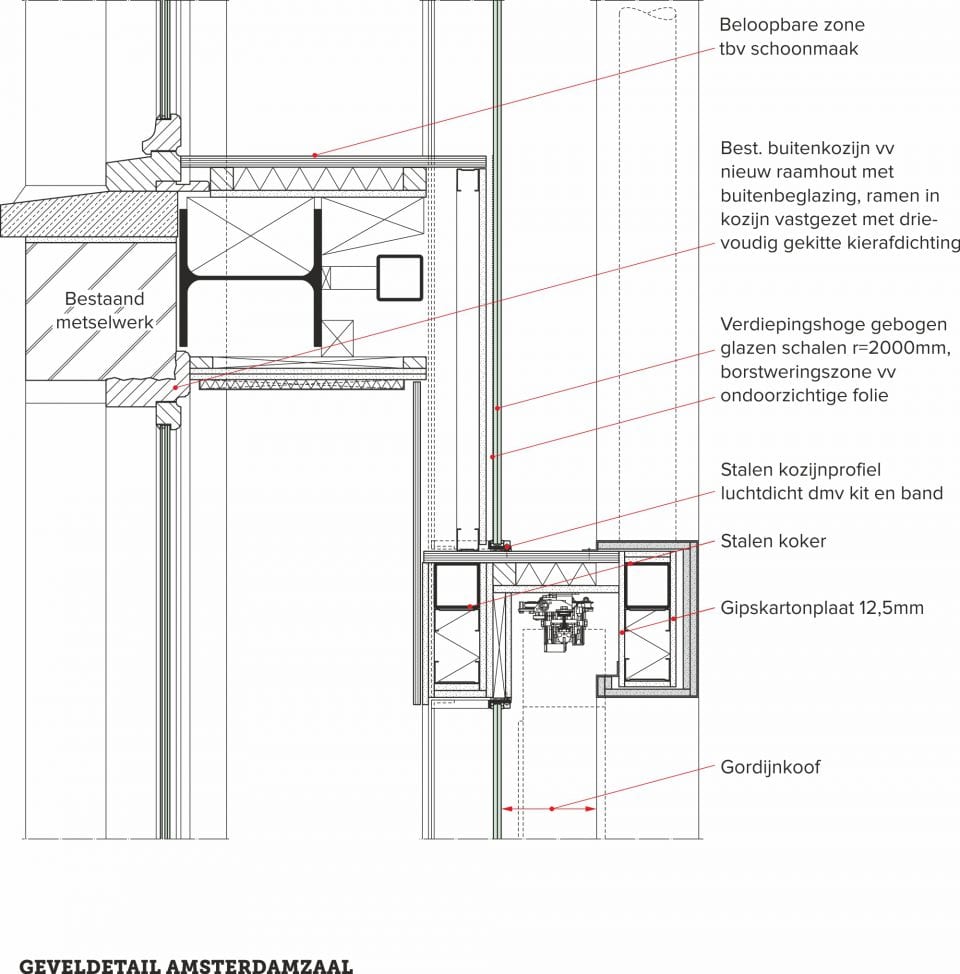

An old school near the Concertgebouw in Amsterdam has been converted into a rehearsal space for the Concertgebouw Orchestra: RCO House. The building includes an ensemble hall for chamber music. To make this possible, four existing classrooms have been merged by partially demolishing the walls between two classrooms and the floor of the first floor.

In the hall an extra inner facade has been created with floor-to-ceiling glass dishes. These convex panels distribute the sound and prevent unwanted reflections. A walkable zone has been created at the height of the old first floor and the outer facade for cleaning work.

Aluminium composite as the fifth facade

The new climbing hall in Leeuwarden has a shape that is functionally determined. An image of a reclining rock is based on this form and function of the hall. A relief in the aluminum siding reinforces that image. The aluminum composite cladding is continued over the roof, which thus becomes a fifth façade. The two kinks that divide the roof into three planes reinforce the 3D shape. The sheeting lies over the water-retaining layer, which consists of bituminous roof covering. The roof is constructed with warm steel roof sheets, the underside of which is perforated for sound absorption.

This entire section is informative only we are not involved.

Floor edges concealed with awning construction

The floor edges of the new construction project Danzigerkade 125 have been concealed at the front facade of this building behind an aesthetic canopy construction, which is composed in height of four facade bands in the colors black, dark gray, light gray and white. Characteristic is that the top black band overhangs the most and the dark gray, light gray and white band protrudes less and less. In order to keep it stable in its shape and also to be able to mount it stable, substantial steel constructions and consoles have been developed. The dimensions were very important, because the visible width of the facade bands, even if they are set back, was not allowed to diminish.

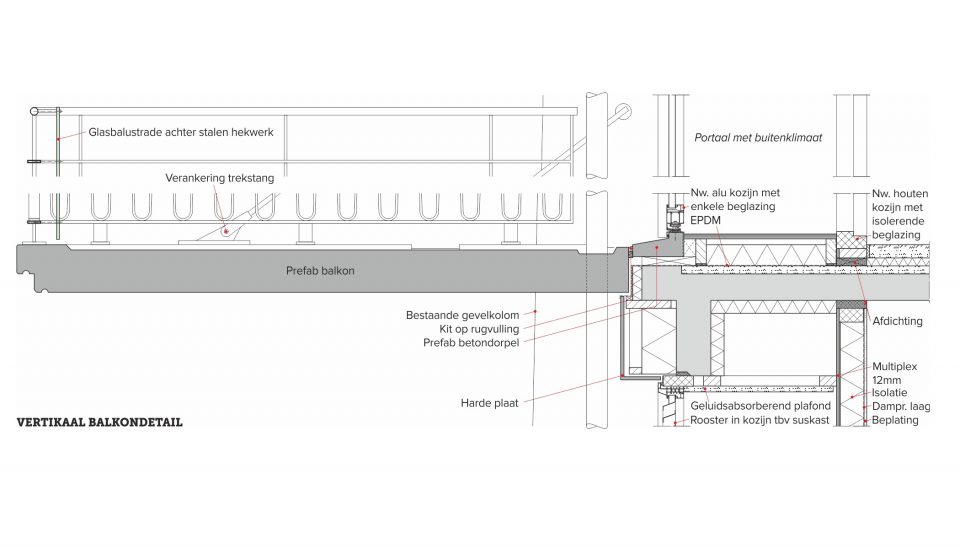

Discreet suspension for new balconies

An office from 1954 has been transformed into a residential building with 85 apartments. For this, new balconies were needed. The balcony panels are 2.7 meters wide and 2.4 meters deep and are placed on steel Z-profiles on the facade and against the columns. They also hang from the façade columns with steel tie rods. To make the suspension as inconspicuous as possible, allow the anchors to engage not on the side but on the top of the balcony slab. The braces at the top are also attached to the existing concrete columns with saucer anchors as low as structurally sound.

Drainage of the frame under the balcony floor

Balconies were installed on the Bilderdijkkade in Amsterdam that, according to the regulations, were allowed to protrude a maximum of 500 mm. To accentuate the windows of the facades, a steel frame was chosen, into which the balcony could immediately be included. To be able to achieve this, far-reaching detailing and careful implementation were required. The balcony consists of steel beams with a floor grid on top. A water hammer has been applied to the steel beams under the grating to direct water from the frame outside the facade surface. The water can drain out of the floor construction through a number of small drainage holes.

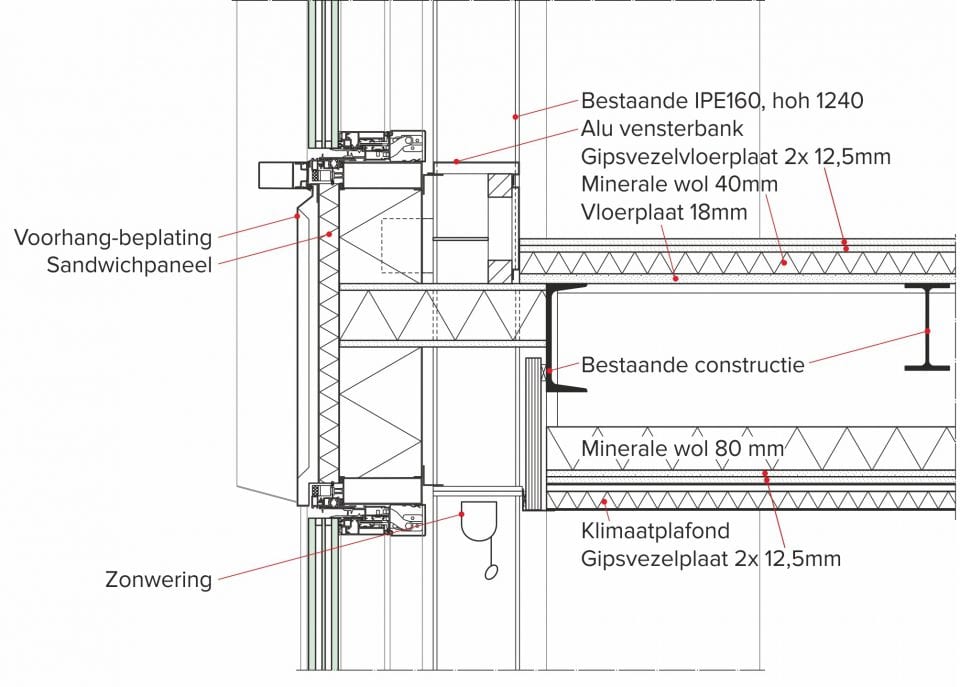

Existing lattice girders reused

The main building of the TU / e has been renovated in a very sustainable way. The lattice girders on the upper floors have been reused for the new floor structure. Due to the acoustics and integration of the installations, the floors and ceilings had to be refinished. The new package had to meet the requirements for soundproofing, but should not be too heavy and too thick. The (climate) ceiling consists, among other things, of 2 gypsum fiber plates and mineral wool. The floor is made up of a floorboard, mineral wool and two layers of gypsum fiber boards.

Sturdy eaves with leaf motif

The semicircular extension to a monument in Leiden has an aluminum facade cladding with a leaf motif. A sturdy roof edge has been created at the top by making it jump forward five times, to which the leaf motif is mounted all around in steps. However, this eaves was not allowed to connect to the adjacent monument in this way because it jumped too far forward. It had beautiful historical ornaments at the location of that connection. By ending the horizontally staggered eaves also vertically stepwise, the connection to the facade has been set back as far as possible.

Tree trunks as load-bearing columns

An old bastei is the basis of a new museum in Nijmegen. Architecturally and constructively, this required various highlights, including ten-meter-high load-bearing Douglas fir trunks. These logs support, among other things, two wooden floors. The wooden floors have been kept as slim as possible and are 70 mm thick. The supporting structure consists of solid wood child beams and laminated timber joists. For the connection of laminated floor beams to the tree trunks, a detail has been developed in which a steel T-plate is screwed to the tree with long wood screws that point 45 degrees upwards. The web of the T is recessed into the laminated beams as a slip plate.

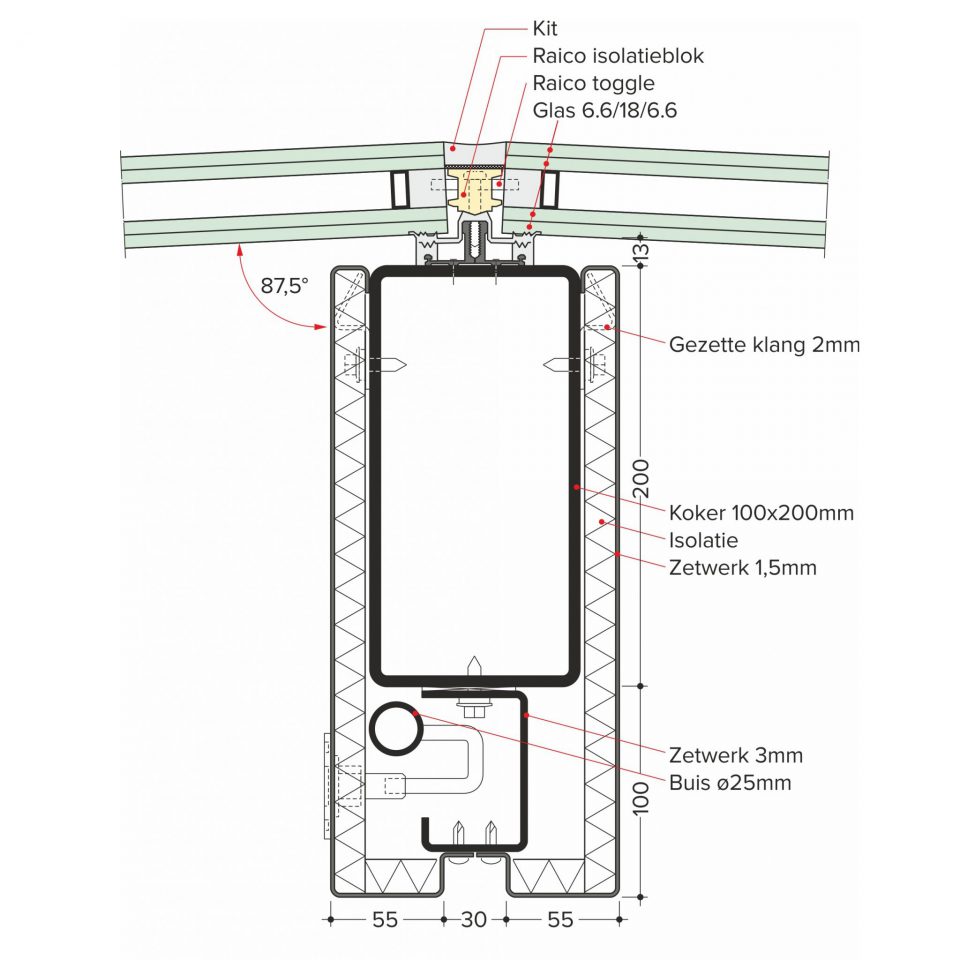

Glass roof diamond exchange

The Amsterdam Diamond Exchange will be transformed into Capital C. A new glass dome will be placed on the roof. The topping out consists of a glass dome with steel frames. The frames are constructed from steel box profiles of 100 x 200 mm. Raico aluminum extrusion profiles are attached to the steel tubes to install the glass.

The glass panels are clamped without visible fixation by toggles in recessed spacers between the glass plates.

Curved balconies

Right on the A10 is a compact residential complex with the musical name Rhapsody in West. Rounded towers jump like musical notes on an elevated ground level.

The continuous façade bands with the balconies presented a challenge. These are made of prefab concrete and poured with iso baskets on the wide slab floors of the building. To limit the number of molds, only three curves were made, which was quite a puzzle. Due to the detailing of the balcony floors, the underside of which is flush with the floors, the step from the balcony to the inside is about 140 mm high. Unfortunately, this is not ideal, especially when it comes to use by the elderly or disabled.

Wooden top with a Dutch climate façade.

The top of the Edge Olympic building is made of wood, with laminated columns and beams left in sight. The choice of wood was the most obvious from a construction point of view, among other things. To form a clear contrast with the existing building layers, the top has been given a full-glass facade. Limiting sun exposure was an important item for the glass façades of the topping-off. To this end, a so-called Dutch climate facade has been created on the east and west façades. This climate facade makes use of the cavity that is created between closed interior sun protection and glass. The warm air is extracted between the interior blinds and glass by means of a cove at the top of the facade. The interior sun protection is linked to the building management system for this purpose.

Biobased construction with Accoya frames.

The Biosintrum had to be leading and innovative in the field of biobased construction. For this reason, a wood construction was chosen that largely consists of locally sourced larch and spruce wood. Originally it was the intention to also produce the frames in larch wood. But they had to be treated first. Because Accoya wood could be used untreated, that material was ultimately chosen. Untreated Accoya is durable and easy to keep clean without affecting the quality of the wood.

Sound reduction with perforated facade.

High demands were placed on the facades of the Amerena Sports Complex in Amersfoort. The main requirement was that they reduce noise. Both inside and out. To realize the latter, the outer construction consists largely of metal sandwich panels with perforated single panels in front. The perforated elements are 3 mm thick aluminum plates with a base size of 1.00 x 2.00 meters, which are set / formed in a box shape with a working thickness of 40 mm. They hang with so-called bed hook attachments, three per side, from special fins. These fins, attached to the rear carrier panels, have a V-shape and protrude well in front of the perforated elements, so that the façade view is divided into planes.

HSB wall with rock wool and insulation foil.

The so-called colony houses are making a comeback, but sustainable. The houses are built with timber frame construction elements. The front house, the part that overlooks the public road, is finished with brick, just like the former living area, and the rear part, which used to be a barn, with covered wooden parts. Thanks to the light weight of the hsb elements and the condition of the ground, no posts are required. The masonry part consists of an outer cavity leaf with 90 mm mineral wool insulation and 3 mm SuperQuilt insulation. This achieves a total Rc value of 5.5 m2.K / W.

Daylight from ceiling islands.

The Strawinsky bicycle parking garage is notable for, among other things, the ceiling islands that are situated above the bicycle racks. The ceiling islands are designed as a tree leaf. The edges are made with sleek white-coated aluminum U-profiles, in which LED lighting is fitted, as well as the emergency lighting. This LED lighting has a warm color and illuminates the paths between the shelves. The ceiling islands themselves are made of expanded metal. Indirect lighting with a cold colour, corresponding to daylight, has been applied above the expanded metal, creating the illusion of skylights. All installations, including ventilation, are also incorporated in these ceiling islands. All installation parts are painted white in order to stand out behind the expanded metal as little as possible. The central pipes and channels to the various ceiling islands have been laid through the concrete.

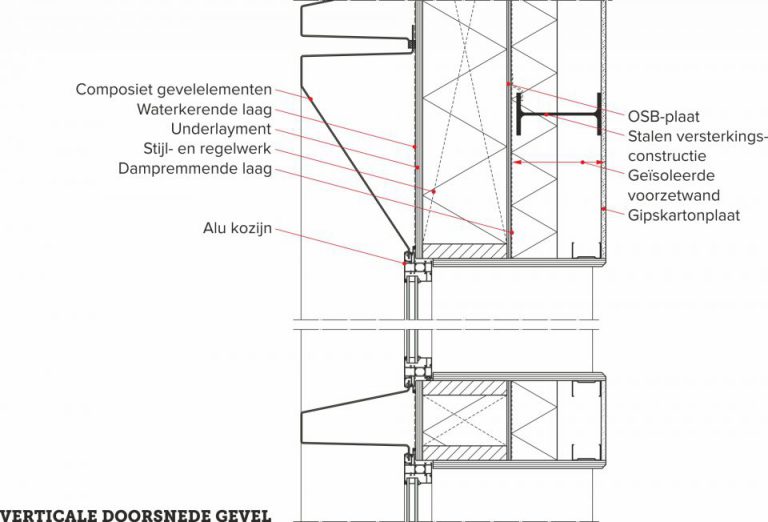

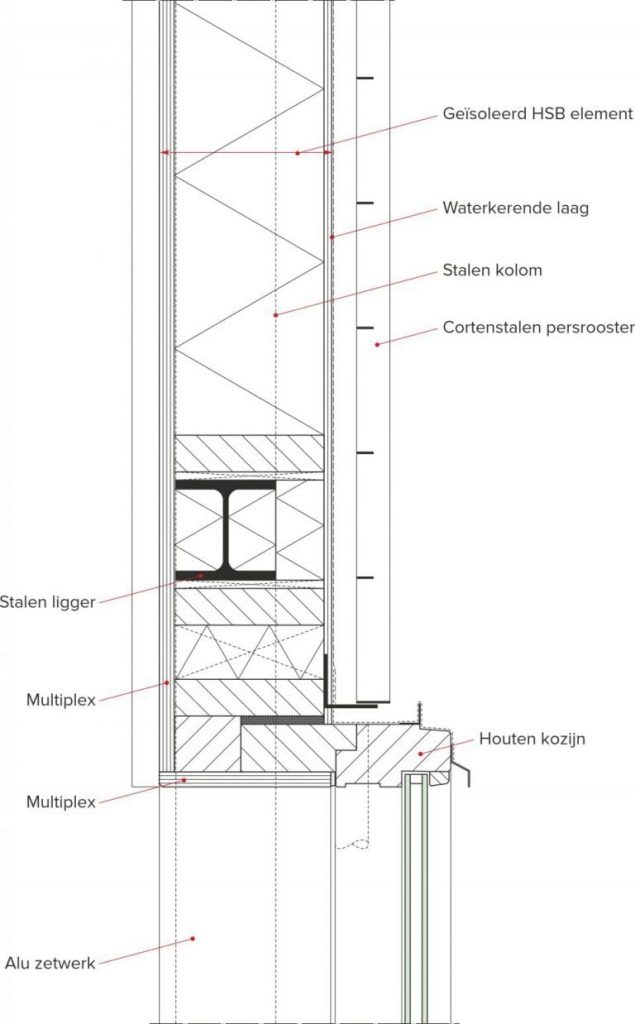

Composite façade against steel reinforced HSB façade.

The Afsluitdijk Wadden Center has a facade of white composite in hexagonal shapes. The composite is attached to a steel-reinforced HSB facade. This reinforced sub-construction was necessary due to the high wind load on the location. On the outside, composite elements are attached to the hsb. These are attached by means of a flange, with which two adjacent elements also overlap each other equally. The composite facade is therefore the raincoat of the building; the hsb façade the thermal shell.

High Light connects to a monumental roof.

The prestigious Capital C, the new center for the creative industry, is located in the monumental diamond exchange. Refined on the outside, industrial and artistic on the inside. The High Light appeals the most to the imagination. Connecting the High Light to the existing work was an enormous job, both in terms of construction, construction and installation technology. The connection to the green roof is made watertight by raising a water-resistant slab against the insulated aluminum flashing. A gravel tray with drainage mats on slope insulation underneath ensures that rainwater can be properly drained.

Reused frames.

The new Emergis children’s and youth clinic in Kloetinge has been built in a circular manner. Many materials, including the frames, come from a demolished office of Rijkswaterstaat in Terneuzen from 2000. The facade design has been adapted to the available frames of the RWS office. The pine frames were still in good condition; however, the paint used at the time had to be replaced because it showed blisters. The frames have been reused in their entirety, including steel frames and horizontal steel grids as sun protection at the top. Even the existing insulating glass has been retained.

Gutters and foil protect glass against rust water.

As facade cladding for Jk House, the architect chose Corten steel walkway gratings. Corten steel is relatively affordable, matches the surrounding buildings and refers to the local past. To prevent the windows behind the grilles from being affected by rust water, a special foil has been applied to the glass. The grids above all visible glass are fitted with carefully detailed drainage channels. That way, descending rust (sky) water will not affect the glass.

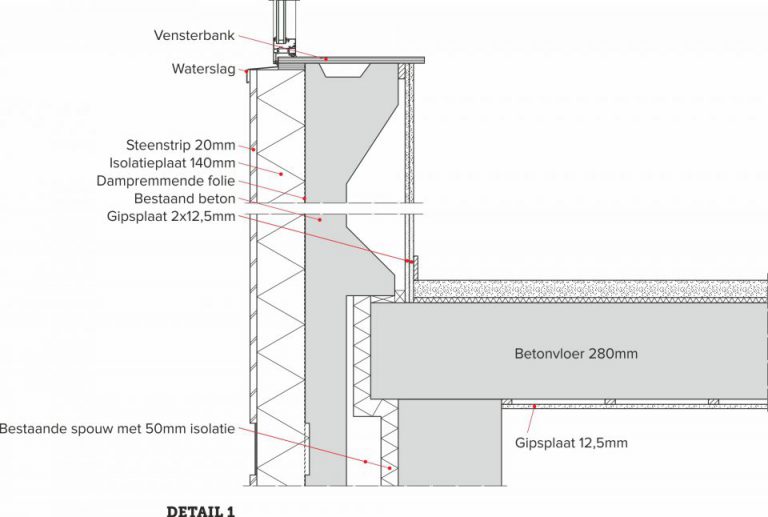

Insulation layer finished with glazed stone strips

A former office building was energetically upgraded from label G to A + during the transformation into an apartment building. An important step was to insulate the outer shell. The façades with the characteristic curves are wrapped in an outer wall insulation system. A 140 mm thick insulation layer has been applied to the existing concrete façade elements. Glazed stone strips in three different shades of green have been applied as cladding. The glazed brick slips have been applied in precise masonry bonds to follow the round shapes of the existing building.

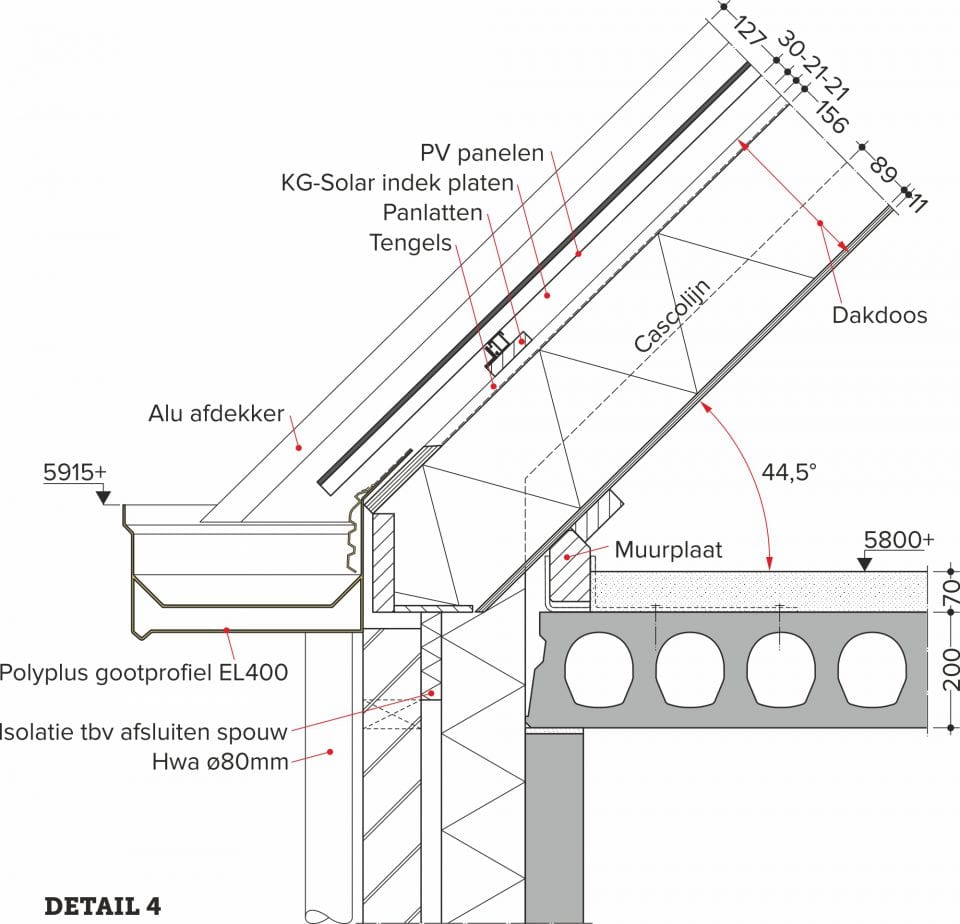

Intigrated solar roof panels.

Gasless construction has been going on for several years on Heiplaat, a historic garden village surrounded by heavy industry in the middle of the port area on the south side of the Nieuwe Maas. The Hidden Geheim project comprises approximately 170 zero-on-the-meter owner-occupied homes with solar panels, among other things. These are installed in the roof on one side of the sloping hood. The other side of the roof box is covered with tiles. Skylights in between are optional.

Closed façade of sandwich panels serves as a pipe shaft.

Installation and building technology are fully integrated in Nathan’s new office. The north-eastern end façade of the building is completely closed. This is a double wall that is used as both vertical and horizontal pipe shaft. The outer wall of this consists of steel sandwich panels, on which a covering of concrete composite tiles has been applied. The tiles have variable dimensions and are glued to a ventilated construction with aluminium posts. On the inside, a partially unobstructed view of the pipe shaft has been created by means of a glass wall, in order to make the installation technology visible.

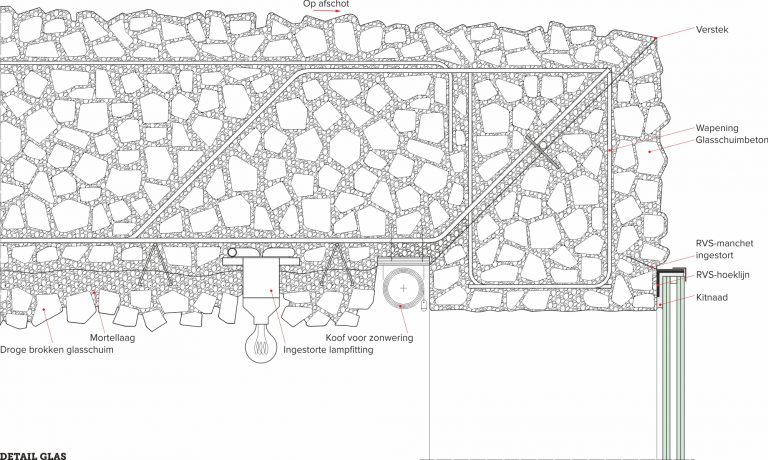

Glazing installed cold against insulating concrete.

The regional office of Natuurmonumenten near Zierikzee is made of insulating glass foam concrete. The way in which the glass is placed is striking. In fact, it is “cold” glued to the concrete construction from the outside, with an overlap of about 100 mm. Such detailing is therefore possible with insulating concrete. Of course, the window is framed and attention has been paid to moisture resistance in the connections. A stainless steel profile 60 x 60 mm has been used as the window frame, with extra constructively cast ‘hands’ at the bottom. This frame is fitted with a stainless steel collar all around, which is embedded in the concrete as a moisture barrier. The frame also features stainless steel bar ends that are clamped behind the traditional reinforcement to allow for wind suction. The frame is completely pre-applied to the wall formwork and cast into the wall.

Wavy balcony balustrades.

During the upgrading of the exterior of three housing blocks on the Helderse Waddenzeestraat, the entire architecture of the houses was opted for a link with the sea and beach. For example, the aluminum balcony fences have a corrugated bar and the stone color is derived from the sand on the beach. The old – poured-through and partly indoor – balconies have been sawn off along the facade line. The new balconies have been enlarged by means of Hi-Con ultra-high-strength concrete floor slabs. The new plates are placed on consoles on a steel construction that is incorporated in the cavity.

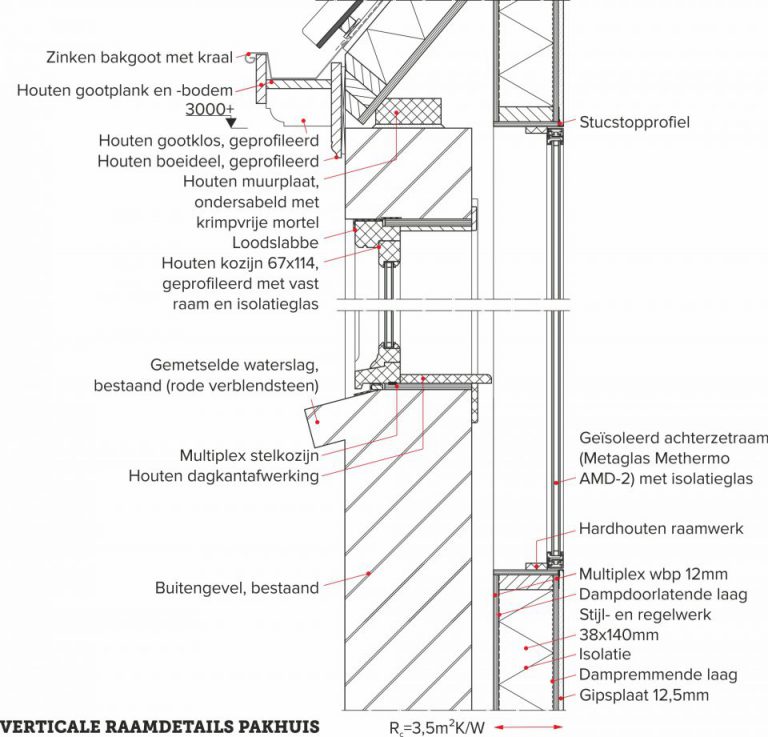

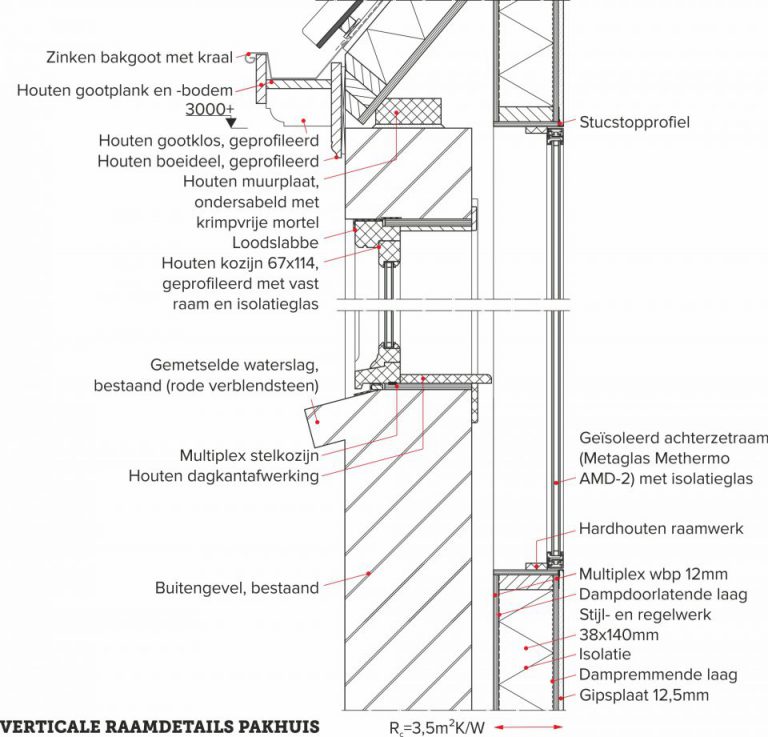

Historical facades of warehouse retained.

After a fire in 2014, what remained of a historic warehouse

in Leeuwarden only two facades. The two facades have been reused in the construction of the new NHL Stenden silence center. However, the monuments were not allowed to make the facades an integral part of the new building. For this reason, the historic warehouse has been rebuilt in its original form, with the original roof shape and roof pitch. The inside could be new. That is why the new frames have been placed in the existing brick outer wall. The inside consists of an HSB retention wall, with an insulated rear retention window.

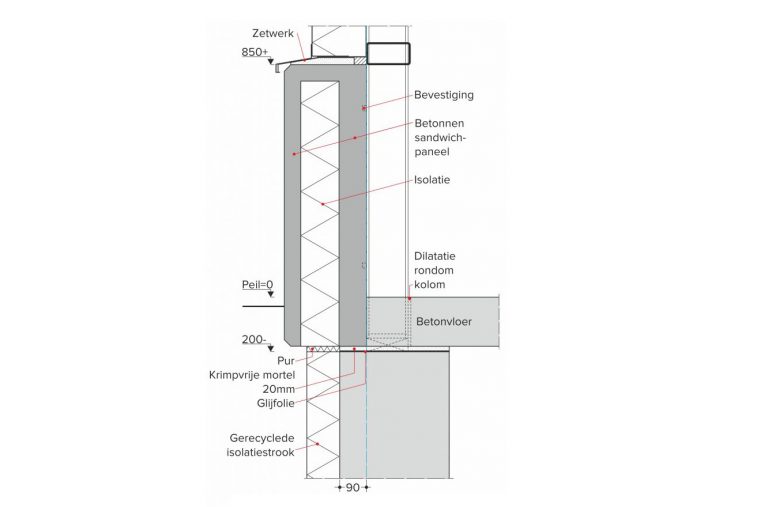

Sandwich panel with recyclable insulation.

On a business park in Deventer, a circular energy-neutral business building has been placed on a plot that will be completely released for another function after 25 years. To limit the emission of toxic gases and energy consumption, the steel supporting structure of the hall was not welded, but assembled with nuts and bolts. The concrete sandwich panels are insulated with BioFoam. This is a product that can be fully recycled into new insulation in 25 years.